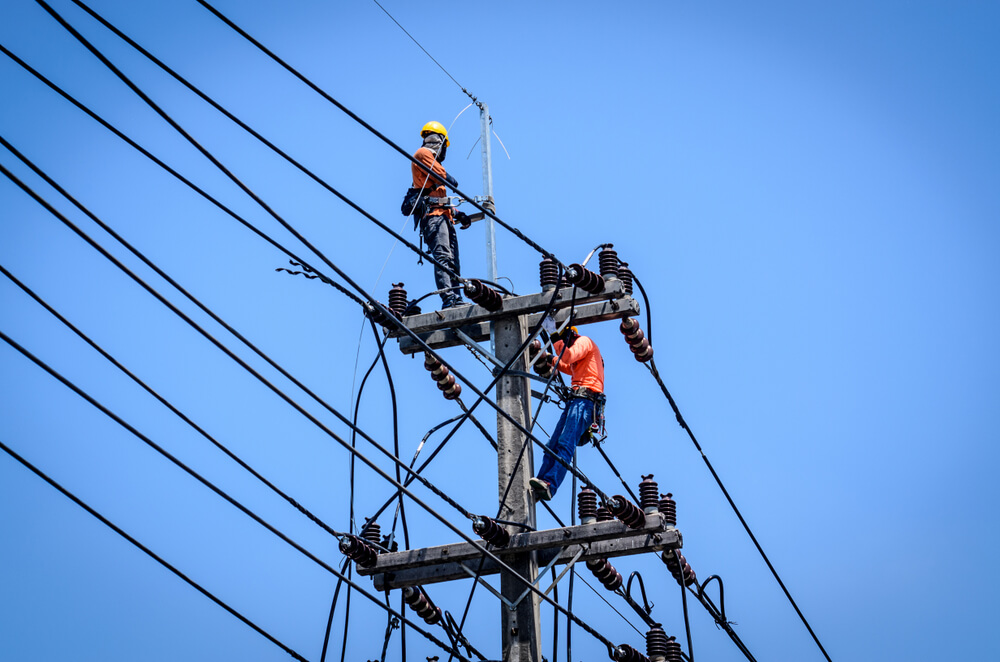

Aerial Lifts and Power Line Hazards

Many types of aerial lifts are used when working near power lines. Scissor lifts are often used because they tend to be more stable. Telescopic booms tend to be used when working heights exceed 50 to 60 feet. Because they can extend out as well as up, they are often used when working on and around electrical systems. No matter what type of lift is used, power line hazards must receive workers’ full attention.

Electrical accidents occur for many reasons. The most common include a failure to maintain a safe distance from the power lines; moving the boom in the wrong direction; not knowing the cable voltage; lack of training and certification of lift operators; and not following power line hazard safety guidelines.

The #1 Job Site Hazard Working on Power Lines

The biggest risk is a worker or the lift making contact with a live cable. Eager to learn how to avoid power line hazards in this type of accident? Turn off the power before starting work. Of course, this may not always be possible. There may not be a qualified person on-site to shut off the power. Or, the power utility may refuse to shut down the line if it would cut off the public energy supply.

When live power lines can’t be shut down, safety procedures should include: shielding the cables; using insulated aerial lifts designed to work near cables; keeping a safe distance by using power line proximity indicators; not allowing the boom to get too close to the cables

More Electrical Hazards Working Near Power Lines

Making contact is not the only hazard of working near power lines. When working on or near live cables, lift workers should wear insulated clothing and gear at all times.

Another hazard when working on power lines is setting up the lift on unstable ground. This is one of the worst aerial lift hazards. It can lead to tip-overs of the lift, which can cause accidental contact with the power line. Working in high winds can also lead to tip-overs.

Electricity jumps are another common powerline hazard. Electricity can “jump” through the air. When this occurs, lift operators can get shocked without touching the cable. The higher the voltage in the cable, the further electricity can jump. Moist air can also increase the jump distance.

Protecting against these non-contact shocks means using the Minimum Safe Approach Distance (MSAD), having extra supervision when working around live power cables, and having an emergency plan in case of an accident.

What is Minimum Safe Approach Distance (MSAD)?

MSAD is the minimum distance lift workers should keep between themselves and live power lines. It starts at 10 feet of clearance and goes up with the voltage of the cable. Always determine the correct MSAD before starting the job.

Voltage MSAD (in ft.)

0 – 50,000 10

50,000 – 75,000 11

>75,000 – 125,000 13

>125,000 – 175,000 15

>175,000 – 250,000 17

>250,000 – 370,000 21

>370,000 – 550,000 27

>550,000 – 1,000,000 42

If work conditions make it hard to keep the correct MSAD, stop work. Then inform the safety consultant. The utility firm may need to de-energize the power lines before workers can get back on the job. If not, it may be possible to insulate the cables.

When to Use the 30- and 50-Foot Rules

Working near power lines on an aerial lift closer than the following distances is allowed: 30 ft. and a fully extended boom from cables on wooden pole, and 50 ft. and a fully extended boom from an electrical pylon.

An expert from the utility firm should identify which cables are live; their voltage; the correct MSAD based on the voltage; and any extra measure needed to work safely.

Generally speaking, the higher the voltage, the more distance must be put between the lines and the workers. When in doubt, keep back from power lines. It’s simply not worth working near power lines when you’re unsure of their voltage.

Power Line Safety On the Job

Keeping safe on the job site is of utmost importance. With a little foresight, you and your team can learn how to avoid power line hazards. Lift workers should be aware of all live electrical equipment in the area. This includes overhead cables because they are rarely insulated.

You should always inspect the worksite before starting the job. Look for any live cables that could put workers at risk. Then place warning signs to point out any hazards.

When setting up aerial lifts, tools and devices that can conduct electricity should not enter the MSAD zone or contact power lines. Setting up or moving aerial lifts around overhead power lines can increase the chances of an accident. Use a “spotter” to ensure that clearance between the lift and the cables does not breach the MSAD.

Never extend an aerial lift above live cables. When doing electric welding work, do not use any part of the lift as an electrical ground. Train all lift workers how to safely work around the electrical hazards on the job site.

Aerial lifts provide a safe way to work at height when safety measures are used. When working around power lines always assume all overhead wires are live and carry a lethal voltage. Never assume a wire is safe to touch, even if appears to be insulated. Stay at least 10 feet away from overhead wires during cleanup and never touch a downed overhead power line.

Key Questions to Ask

They say knowledge is power, and that’s never more true than when you’re working near power lines. Each day on the construction site, it’s helpful to ask several questions about the situation at hand. Discover whether there are any power lines in the area. Determine what, if any, precautions have been taken. Check whether or not dangerous situations have been communicated to the onsite workers. Ask if anything has changed since the previous work day. Also consider whether there might be any new workers who might not be familiar with the site and its hazards. The answers to these questions can help you avoid many of the most common hazards of overhead power lines.

Prioritizing safety at the job site is key. Making this a collective goal for your entire team can help everyone stay that much safer at work. By looping workers into your goals for a safe work environment, you enlist their eyes and ears for spotting hazards you might have overlooked yourself. Well meaning pedestrians, mechanical lines under pressure, and mobile equipment placed too close to the work site can all present new safety challenges to overcome. By working as a team, you can make job sites safe even when power lines are present.

Aerial Lift Safety Training and Certification

All lift workers should be trained and certified when working near power lines. It is required by OSHA, and can save the lives of employees. AerialLiftCertification.com (ALC) provides fast, affordable training for aerial and scissor lifts.

You may be surprised to learn our courses are quicker, easier and more affordable than you think. They can be taken anywhere you have an Internet connection. They can be completed in about an hour. And workers can print their certification cards as soon as they complete the course.

Protect your employees and your business with OSHA-approved aerial lift training from FLC! To learn more or get started, click here or dial 888-278-8896.